Project in numbers

230m3 The stormwater-holding capacity created by the new tank

0 The amount of power required to run the sustainable self-cleaning maintenance mechanism

The need

The government’s Storm Overflows Reduction Plan aims to reduce overspills of untreated wastewater into UK rivers by increasing the amount of stormwater storage on treatment sites. Our client’s site required 230m3 storm water capacity to achieve compliance with the new regulations.

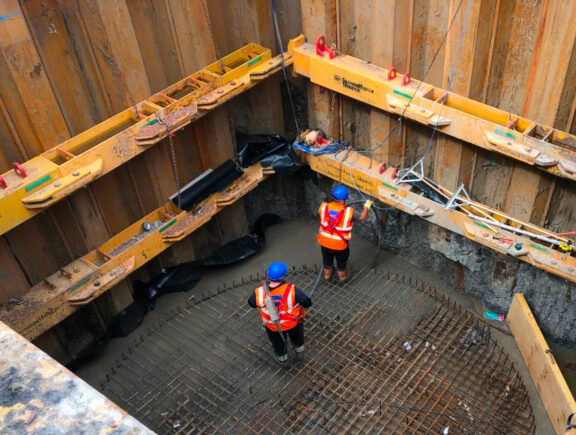

There were several challenges that we had to address in the planning and delivery of the additional stormwater storage tank. Constraints included a tight deadline due to the regulation compliance date, limited space and access restrictions created by working on an operational site, and high levels of groundwater due to the high water table during the winter months.

The solution

To create a new tank within the available site footprint, we demolished three redundant brick tanks. We designed the new, pre-tensioned tank with the use of off-site manufactured pre-cast concrete panels and carried out a concrete pour on site for the base, to ensure completion before the compliance deadline. The pre-tensioned design enabled us to put the tank into service immediately upon installation and undergo reinstatement of the excavations and remaining completion works after the tank was operational.

We managed the excess groundwater by installing permanent pumps throughout the duration of the programme, which pumped water away from the construction area and back into the head of the works where it was constantly monitored for contaminants and turbidity. Contaminants and sediments were filtered through silt tanks prior to discharge to eliminate the risk of pollution.

The tank is gravity fed and features a sustainable Eliquo Hydrok Controlled Water Flush (CWF); a self-regulated device which cleans sediment from the tank. The system drains hydraulically by gravity and automatically empties stored water after the tank empties, flushing the floor surface.

The benefits

- The hybrid construction approach, using pre-cast concrete panels to form the sides of the tank, enabled us to deliver the new tank within a shorter timeframe, as well as driving down the overall carbon footprint of the project. Pre-cast panels have the added advantage of improving on-site access and safety.

- The pre-tensioned tank design also enabled the tank to be put into operation sooner.

- The gravity-fed design removes the need for energy-intensive pumps, reducing ongoing costs and emissions.

- The Eliquo Hydrok Controlled Water Flush (CWF) requires no power to run and eliminates the requirement for regular maintenance in the form of jet washing, saving our client time, running costs, and unnecessary carbon emissions.

- The design features which led to a more sustainable and efficient delivery helped our client reduce carbon emissions while significantly increasing stormwater capacity to help protect local waterways.