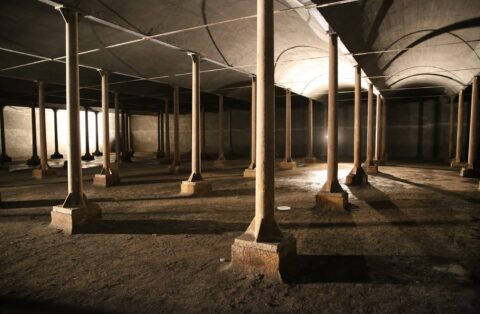

Following coating trials and pull off tests, we applied a sprayed shotcrete application to the full wall area. This was to provide negative pressure protection against ground water ingress, followed by an application of a 2mm thick cementitious tank coating.

The inlet, outlet and washout pipework was grit blasted to remove all traces of corrosion and subsequently protected by the application of a urethane based coating.

Externally, the concrete barrel vaulted roof was strippedof deep soil/ clay overburden by otherswhich exposed a debonded asphalt lined slab and various areas of major structural damageat the vault ends and upstand locations. We removed the asphalt lining by mechanical means followed by an abrasive blast to remove all remnants of bitumen primer and lose and friable concrete. due to the condition of the substrate and to provide a suitable surface on which to lay the subsequent water proof membranes a sprayed shotcrete levelling screed was applied to the full area. Structural designs were completed for the structural repairs to the arches and upstandswhich were completed after all necessary temporary works had been designed and installed.

The roof was water tested following the shotcrete application in order to satisfy the structure was water tight before the secondary protective waterproof membrane was applied.

Due to the problems of historical wall ingress it was decided that a lined roof level drainage system be installed to stop drainage water from the roof percolating to the lower face of the outside walls. This was then taken to a site drainage chamber 50 meters away.

Before reinstatement the roof was lined with a cuspated drainage sheet to assist the drainage of the heavily clay based overburden which led into the perimeter roof drain.

Following the installation of a new ladder, a final clean of the tank was completed together with a post clean inspection chlorination and the tank was handed back to the client for filling and testing..