A loose-lay Flagon solution was selected to guarantee the asset’s rapid return to service without the risk of disruptions. To meet the deadline, Stonbury deployed additional labour to work during extended hours and weekends, which included its new team of highly skilled in-house liner specialists, specially trained to weld thermoplastic membranes.

During the planning phase structural engineers calculated the weight of the loose-lay liner system and the installation process to ensure the structure was safe to work on. Results informed a method of working which involved placing operatives systematically to avoid putting too much weight on each bay.

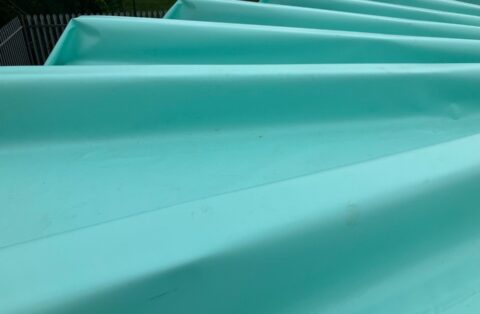

Installing the liner on the panelled circular roof required meticulous attention to detail and involved carefully measuring, pre-cutting and intrusion welding hundreds of pieces of Flagon. Once the installation was complete, the roof underwent MIT-sensor testing, a flood test and a clean and chlorination.

Although the loose-lay liner is classified as a semi-permanent solution, it is highly robust and offers long-lasting resilience to thermal movement. The solution has significantly increased the asset’s longevity and provided assurance that the tank will remain waterproof for many years to come.