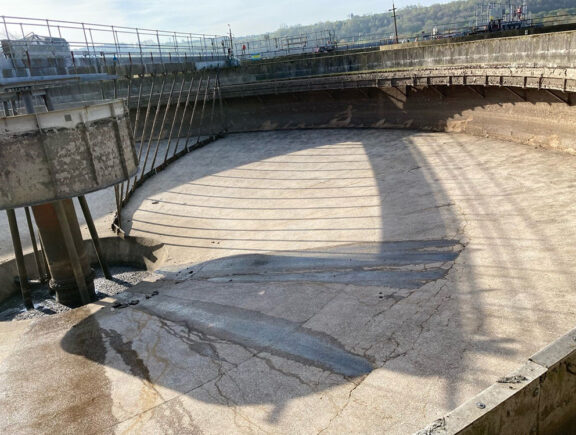

After a site induction with the client, the team prepared the surfaces for the repairs using angle grinders. Work then began to tackle leaks on the perimeter joint sealing using a natural cementitious material to provide a solid surface prior to applying overbanding.

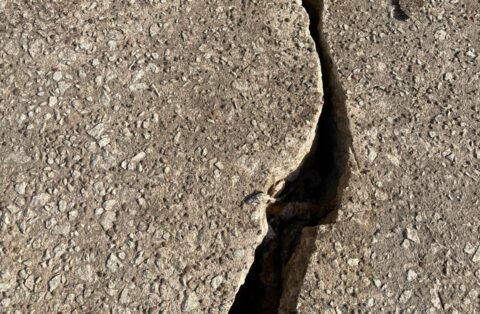

The floor surface required various other methods. A large floor crack was repaired using a non-shrink grout, due its size of over 80mm in places. Overbanding was then applied to the crack. Several smaller cracks were repaired by applying a cementitious slurry coat which effectively seals by soaking into cracks.

In some areas overbanding was not possible due to paddles on a rotating arm within the tank passing close to the floor which posed a risk of damage to the raised material, therefore in these areas resin was injected prior to infilling the joint with a fast-setting mortar.

In total approximately 50 metres of cracks were sealed and 80 metres of overbanding was applied during the week-long project. The client was extremely happy with the result and the team, who worked over a bank holiday weekend, attending site on both bank holiday Friday and Monday.