Whilst the lower levels of the steel tanks were in reasonable condition, the higher levels had such severe corrosion; holes had appeared within the steel plates effectively reducing the operating levels within.

A repair proposal was formulated utilising a 100% solids Urethane hand applied protective coating system, incorporating fibreglass matting embedded in epoxy adhesive, to cover all areas damaged by the corrosion.

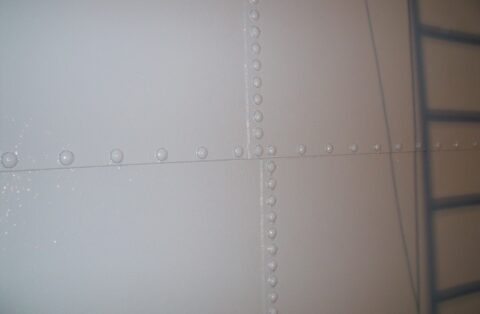

All extruded bitumen jointing compound was removed, by hand scrapers, from all panel joints and bolt heads.

The internal faces of the tanks were then grit blasted, using the quill dustless blasting system, to remove surface corrosion and expose further damaged areas.

All prepared damaged areas were then overlaid with fibre glass patches embedded in epoxy adhesive.

All joints, bolt heads and patches then received 2 full ‘ stripe’ coats of the urethane protective coating, after which the full internal area received 2 further coats of the system.