The scope of works

Internally;

- Prepare and overband wall and floor joints.

- Installation of new stainless-steel access ladder

Externally;

- Removal of external roof slab overburden

- Excavation of perimeter trenches

- Installation of a loose laid membrane

- Waterproofing detailing to upstands

- Installation of new roof and perimeter ducting for site security/telemetry

- Reinstatement of gravel

- Install new sample tap/kiosk

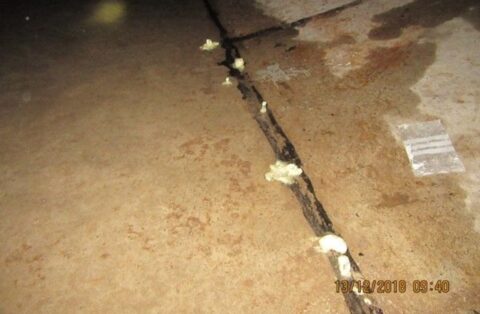

During the internal overbanding works, substantial ingress was identified in various locations along the existing floor joints. In an attempt to seal the leaks, bunding was used on the identified ingress points, however the team were still required to pump water from the cell on a daily basis.

A polyurethane resin injection system was then used to form a watertight seal, allowing material application and curing to proceed. Ingress was also identified around several of the column bases, resulting in additional overbanding requirements. Once complete, there was a significant improvement to the volume of ingress within the cell. Concrete repair works to the internal substrate were also carried out, including repairs to additional hairline cracks identified in the floor slabs.

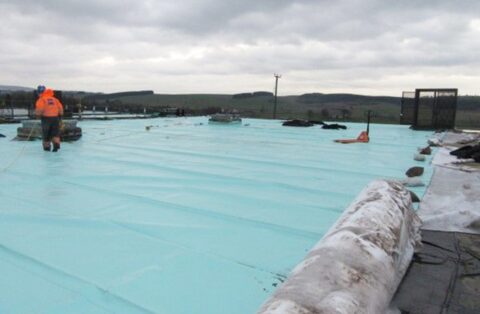

Externally, the gravel overburden was removed by a combination of hand and vacuum extraction, to increase productivity and reduce both the manual handling impact and repetitive strain risk to the team. Once preparations were complete, the new loose lay membrane was installed. Along the dividing wall between the two tanks, the membrane was temporarily held down with a chain of sandbags and timber ready for the next stage of the project.

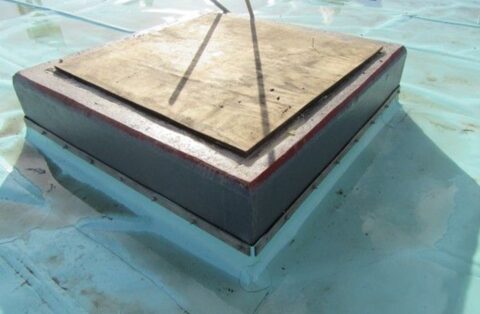

The team then focused on the uplift and re-bed of the existing hatches. Due to voids within the base plate, concrete repair mortar was used to make watertight before the hatches were reset into position and a liquid membrane was applied. Geotextile was then installed on the roof and the gravel overburden was reinstated. The cell successfully passed the GCMS sampling process and was returned to service by the client.

The second cell presented similar challenges with regards to internal ingress from the floor slabs, joints and columns. The team onsite were also impacted by extremely cold and windy weather conditions, so further measures were taken to ensure the work could be completed. This included the installation of heating inside the tank to keep the temperature above 10 degrees 24 hours a day, ensuring the specified DWI Regulation 31 curing temperatures were adhered to.

On completion of the internal and external works, the second cell successfully passed the testing and sampling process and was returned to service.