Working with design partners, Stonbury designed a central dividing wall, comprising of 400mm thick reinforced concrete. In addition, the scope included a new opening into one half of the reservoir and a valve chamber within the new reservoir for the isolation valves for the outlet pipework, washout and overflows.

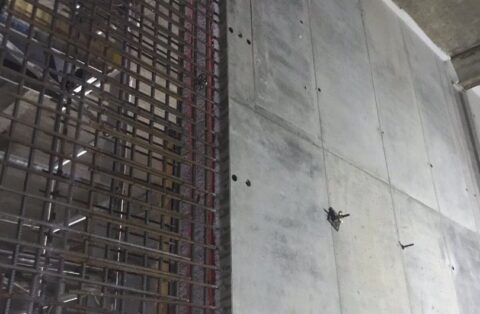

Initial works involved preparation to the reservoir floor by scabbling the surface. Two lines of starter bars were then drilled and fixed into the floor slab and walls to allow for the installation of the formwork for the kicker upstand. Once sufficient reinforcement and shuttering was in place, the kicker was poured and left to cure.

The kicker had to be cast to a height of 1.5m, as opposed to the usual 100mm or 150mm, this was to enable the use of lightweight shuttering inside the reservoir, as each piece had to be manually lifted into place. Limited access into the tank also restricted the type of formwork that could be used and the maximum pour height that was available with that type of formwork system. To lift the shuttering panels to the top of the wall, the team required the use of wind up platforms. The remainder of the wall was poured in sections to avoid cracking and ensure longevity.

Holes for the new inlets were cored out and works began to cut out the new doorway into the chamber. Once complete, a demolition robot was used to break the concrete out, allowing works to begin on the pipework. This included casting the outlet pipework and washout into new concrete.

New pipework was installed in both sides of the reservoir and pressure tests were carried out prior to cleaning and chlorinating the pipework. The old flow meter was also replaced with new and the gate valve on the washout pipe was removed.

To complete the works, new GRP access ladders were installed and two new Technocovers were fitted on one side of the tank. The team also re-bedded the existing hatch covers to prevent any ingress in the future.

The build and return to service of one half of the tank was completed in eight weeks, allowing the temporary tank to be disconnected and dismantled. The second compartment was completed two weeks later.