Project in numbers

400m above sea level

10 years minimum asset lifespan extension

The need

The reservoir was experiencing ingress; therefore the scope was to achieve a fully watertight structure that could continue to meet demand and supply safe drinking water to the surrounding areas. However, at 400 metres above sea level, the reservoir posed major challenges of extreme weather and temperature variation.

The solution

To deal with the low temperatures, we used a natural cement capable of setting as low as 0°C and approved for use with potable water. This enabled us to keep working even when temperatures dropped to near freezing.

To re-waterproof the reservoir, we removed the existing soil overburden and excavated the tank perimeter to access the roof wall-head joint. New perimeter drainage was installed. The roof slab was prepared with high-pressure water-jetting and a cementitious screed. Overbanding was applied to the wall-head joint and all external roof joints, and a new liquid membrane was applied to the roof, and a roughcast system was applied to the walls of the valve houses.

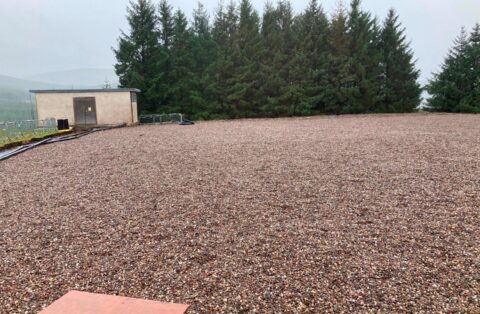

Internal works included leak-sealing, the overbanding of all joints showing signs of ingress, and concrete repairs to walls, columns, and beams. Externally, after completing works to the tank roof, we reinstated a new 20mm washed and rounded gravel overburden and we added perimeter kerbing.

perimeter to access the roof wall-head joint. New perimeter drainage was installed. The roof slab was prepared with high-pressure water-jetting and a cementitious screed. Overbanding was applied to the wall-head joint and all external roof joints, and a new liquid membrane was applied to the roof, and a roughcast system was applied to the walls of the valve houses.

Internal works included leak-sealing, the overbanding of all joints showing signs of ingress, and concrete repairs to walls, columns, and beams. Externally, after completing works to the tank roof, we reinstated a new 20mm washed and rounded gravel overburden and we added perimeter kerbing.

We provided regular client updates via our online client portal, and they were delighted that the project remained on schedule despite the challenging conditions.

The benefits

- The extensive refurbishment extended the lifespan of this large and critical asset for over 10 years without the need to build new

- As an alternative to a new build structure, the completed reservoir refurbishment works had a significantly reduced carbon footprint and overall environmental impact, as well as a substantially reduced price and shorter programme of works

- We secured safe drinking water for the surrounding area